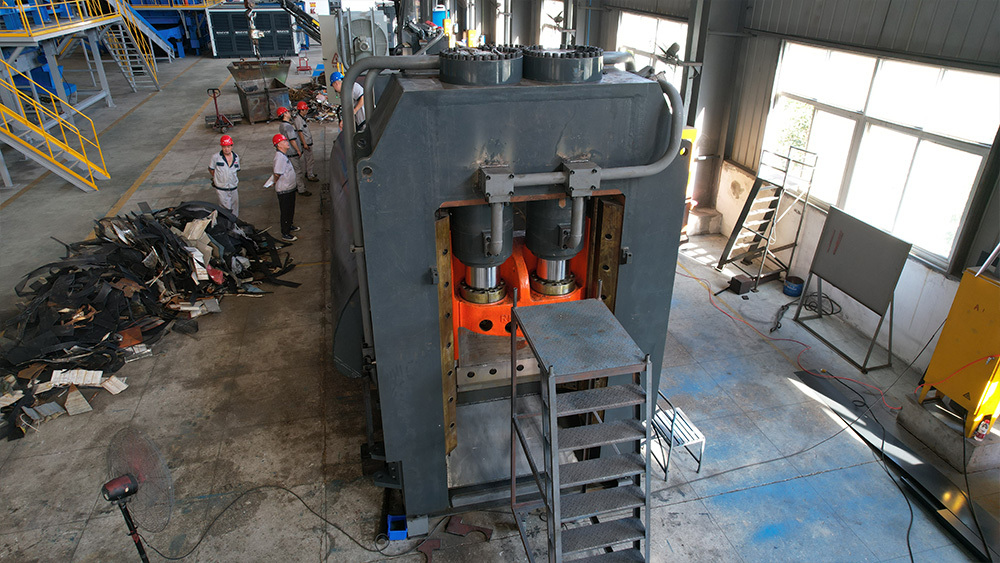

Scrap baler shear

The main machine is composed of two parts: shearing body and compression box.

The body of the shears is welded with high-quality steel plates and forged steel parts, and assembled into the whole body after fine processing.

All sides of the shearing box are equipped with protective plates, which are made of HARDOX400 wear- resistant steel plates, which can greatly extend the service life of the

The guide groove is arranged on both sides of the pressing head of the shearing machine, which can ensure the stable operation of the pressing head and the lower part, and effectively reduce the wear damage caused by partial load to the pressing cylinder.

The sliding seat of the scissors adopts adjustable V- shaped guide rail design, and adopts the friction materials of steel and copper, which can ensure the stable and reliable shearing operation.

The blade of the shearing machine is made of high quality cutter steel after forging, semi-finishing machining, heat treatment and fine machining. The blade adopts symmetrical design, and the four edges can be used for exchange, which effectively reduces the consumption of wearing parts.

Technical Specifications

No. Section Element Values Note 1 Hydraulics Cutting force 250 T x 2 Cyl. Lid force(Left) 80 T x 2 Cyl. Lid force(Right) 80 T x 2 Cyl. Hold down force: 120 T Pusher force: 120 T 2 General Cutting angle 12o Cutting width 900 mm Box size(closed) 5000x800x600 mm Box size(open) 5000x2550x600 mm Overall dimensions(Working) 12748x3480x3100 mm Overall dimensions(Transport) 11200x3480x2400 mm Total weight 48 T Hydraulic oil tank capacity 3000 L 3 Engine Pumps 725 L/min (max:31.5Mpa) A4V250 x 2 Electric motor 150KW 75KW x 2 4 Production Cutting times 3,5/min (empty) Output max 10 T/h Baler size: 800x600mm x variable

Equipment and options

Remote control ✓ A fully functional remote control that allows you to start, fully control the machine manually or automatically for one man operation from the loading crane. Automatic and manual control ✓ The operator can run an automatic cycle when necessary, regardless of the position of the machine components. You can also work in manual mode, each compression can be controlled manually regardless of its position. Touchscreen ✓ A touchscreen control panel installed on the machine monitors a programmable controller (PLC) that controls the manual or automatic functions. GSM modem ✓ The GSM modem enables remote on-line access to all machine parameters, service by the manufacturer's technicians, diagnostics and updates. Automatic lubrication ✓ All moving parts are automatically lubricated by the central lubrication system. Oil heating/cooling ✓ The system ensures continuous operation of the machine regardless of weather conditions and external temperatures. Oil leakage protection ✓ There is an oil tank on the entire surface of the machine, which provides comprehensive protection against any leakage of oil or fuel to the ground. The bowl has valves enabling the discharge of hazardous liquids to properly secured containers. Pressure system ✓ The machine cylinders are equipped with internal pressure sensors to protect the cylinders, allow you to determine their exact position and pressure, which allows for smooth adjustment of the force for the guillotine cylinders or the density of pressed packages.

Production efficiency

Type of scrap Size Cut size Productivity/hour N2 4 ≥ 6 mm 500 mm > 9-10 T/h N7 > 6-8 mm 500 mm > 12-14 T/h N10 < 4 mm 500 mm > 9-11 T/h Rods: 90 mm. Squares: 80 mm. Plates: 50 mm. Automatic packing cycle approx. 1 minute; up to 35 parcels / hour weighing 450-800 kg. Bulk density of a package, depending on the material, from 1.2 T / m3 to 1.7 T / m3 * The test will have a minimum duration of one hour, ideal test duration two hours. The machine efficiency test will be carried out by SIMVIC engineers.

Guarantee

SIMVIC provides a 24-month warranty for the structure and 12 months for the hydraulic and electrical systems. The warranty covers free replacement of defective parts, provided that during normal operation the machine is subjected to regular inspections, which is entered in the service book. Defective parts should be returned to SIMVIC. Travel and service work in any other case is payable. Service response time 48 hours from the failure. The warranty does not cover consumable parts such as: oil filters, knives, friction linings, seals, etc. The warranty does not cover losses (caused by downtime), it covers only parts.